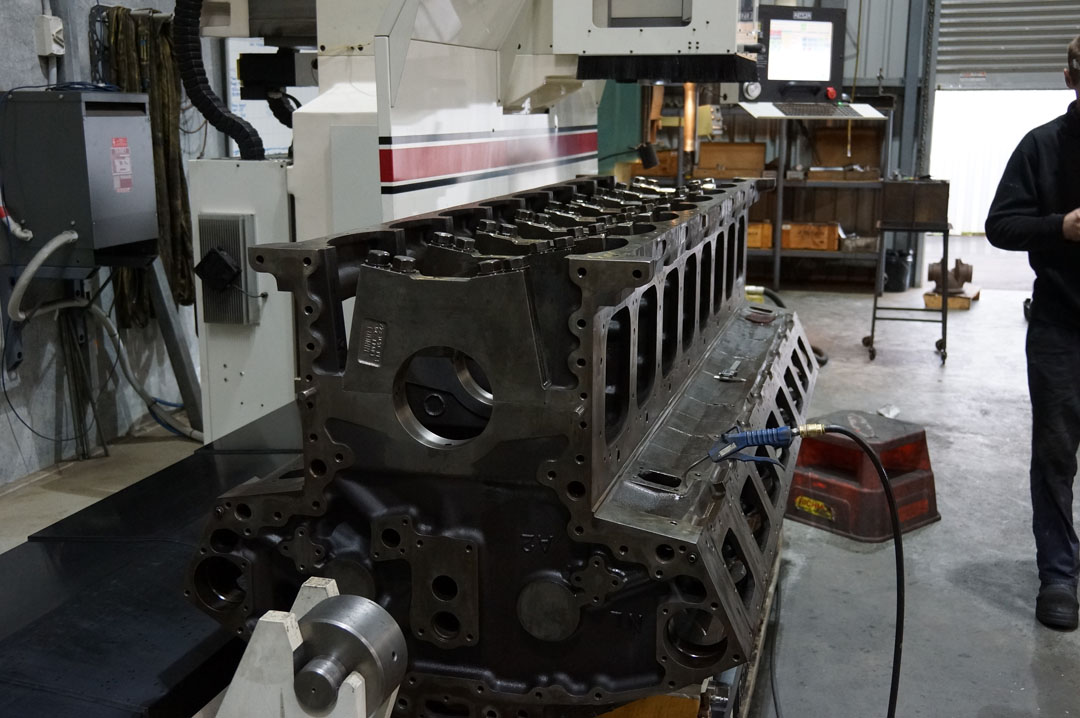

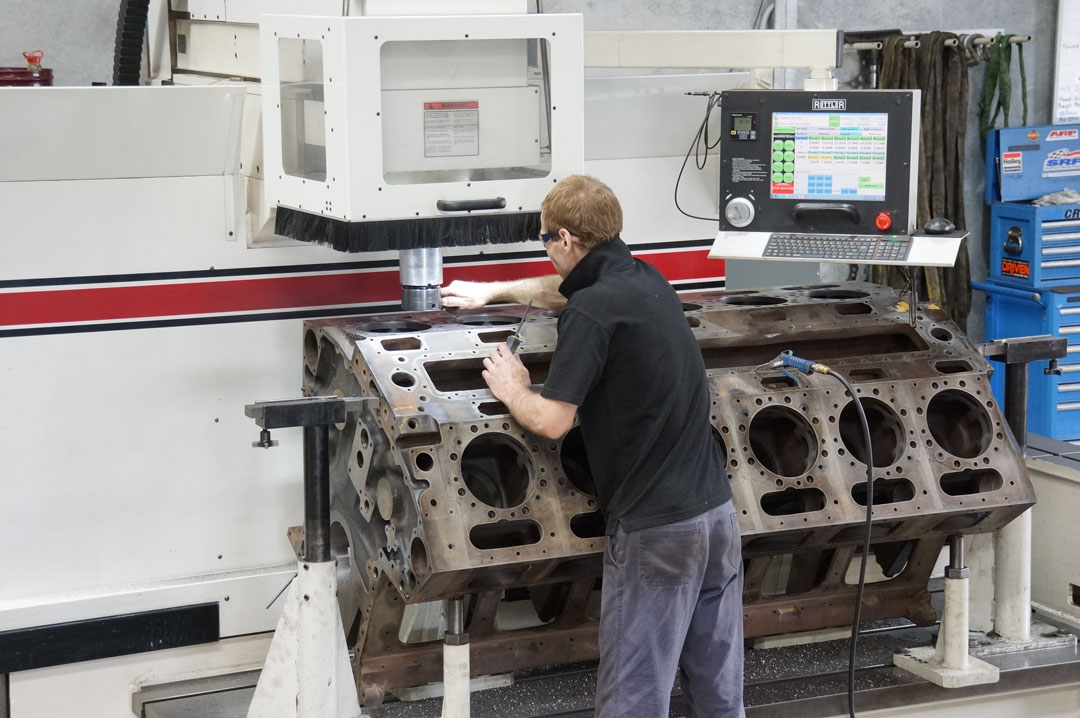

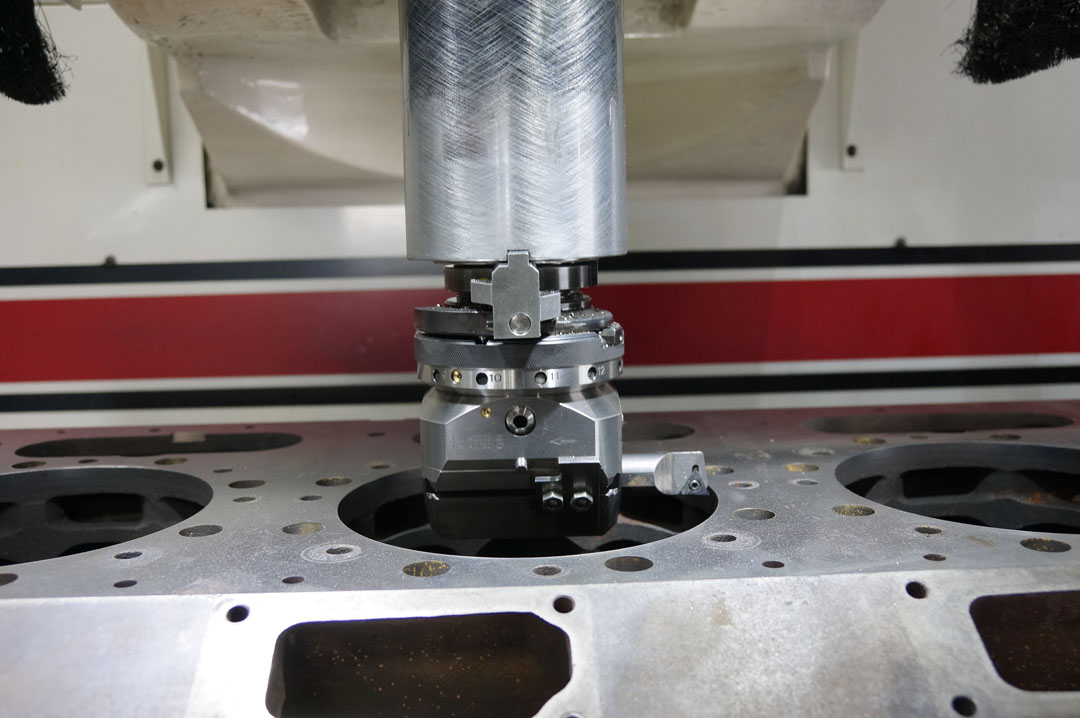

Cylinder Block Machining

From resurfacing to tunnel boring, GTS can completely remanufacture any engine block including the largest CAT 3516, C175-16 & Cummins QSK60 V16 blocks.

Rottler F100 series CNC technology enables us to provide repeatable machining results with accuracy, optimum surface finish and limitless machining capability. The speed in which we are able to process large engine blocks has boosted our capacity and ensures all of our customers down-time is minimal.

Engine block services include: